Creating a culture of safety and efficiency using Hydraulic Mast Climbers

Fall Hazard Mitigation

- Guardrail systems only have to be installed one time

- Tools, storage, and lavatories can be stored on deck

- Cutting, mixing, and processing stations can be located on deck

State-of-the-Art Material Loading

- FRACO can land point loads up to 3,750 pounds

- Max capacity of 8,000 or 10,000 pounds

- Material can be landed via tower or mobile crane

- Gates can open to allow forklift access below 35 feet

- Attachable self-hoist option available

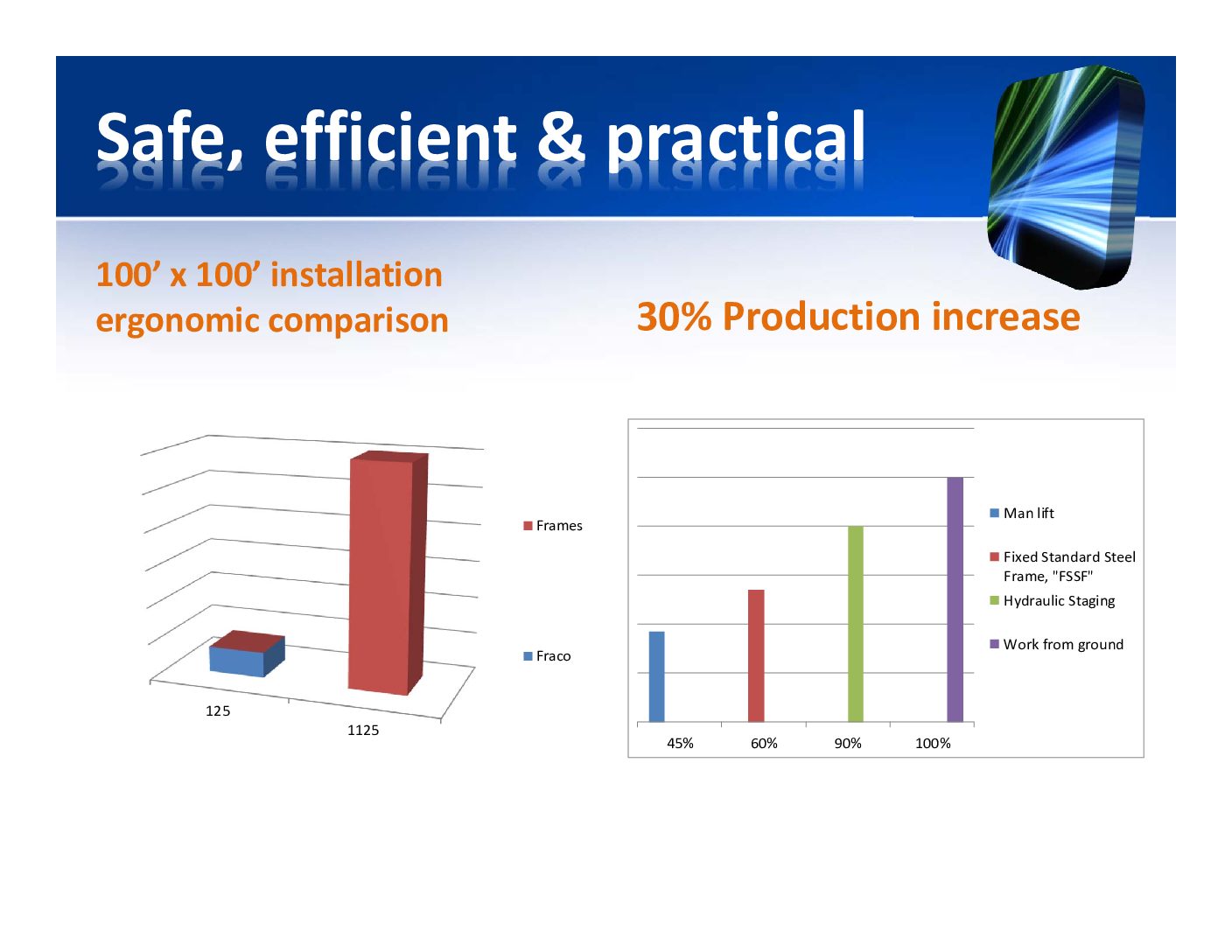

Ergonomically Friendly Equipment

- 85% fewer parts to install and dismantle than conventionally framed scaffolds

- Materials stored within close proximity

- Materials, personnel, and tools travel together

Training

- User Operator Training Videos:

- Installer/Technician Training Classes Annually

Next Installer certification workshop will be held in Carnation Washington on April 23rd thru the 26th- 2019.

Call or email for details:

(800) 813-7780

Info@sunscaffold.com